It is the speed at which a workpiece passes through your router’s cutting edge. The cutting speed of your machine is represented in meters per minute (MPM) or surface feet per minute (SFM). The cutting speed of your CNC router is computed using this formula: Cutting Speed = π × Diameter of the Tool × Spindle Speed.

Features and Characteristics

Here are some key features and characteristics commonly associated with a CNC router 1325:

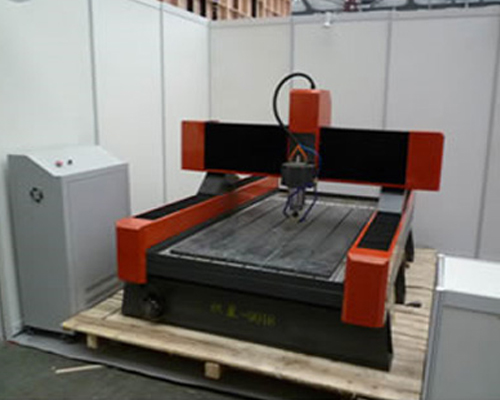

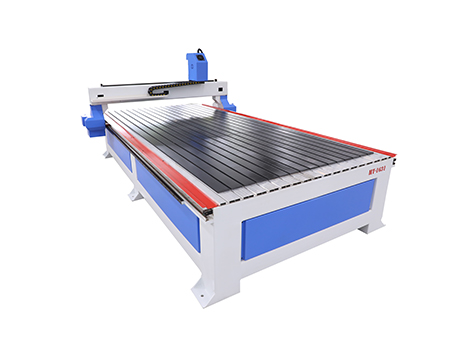

Working Area: As mentioned, the 1325 in the name represents the working area or bed size in millimeters, which is typically 1300mm by 2500mm. However, there can be variations in size depending on the manufacturer and specific model.

Spindle: These machines are equipped with a spindle motor for cutting and carving. The power and speed of the spindle can vary depending on the specific model. Typically, you can find machines with spindles ranging from 1.5 kW to 5 kW or more.

Tool Changer: Some advanced CNC routers 1325 may come with an automatic tool changer, which allows you to switch between different cutting or carving tools without manual intervention. This is especially useful for projects with varying tool requirements.

Control System: CNC routers are controlled by a computer system that interprets the design files and translates them into movement commands for the machine. The control system can vary, but many machines use software like Mach3, LinuxCNC, or proprietary control systems developed by the manufacturer.

Construction: The frame and structure of a CNC router 1325 can be made from various materials, with steel or aluminum being common choices for rigidity and stability.

Material Compatibility: These machines are versatile and can work with a wide range of materials, including wood, plastic, acrylic, MDF, composites, and even non-ferrous metals like aluminum.

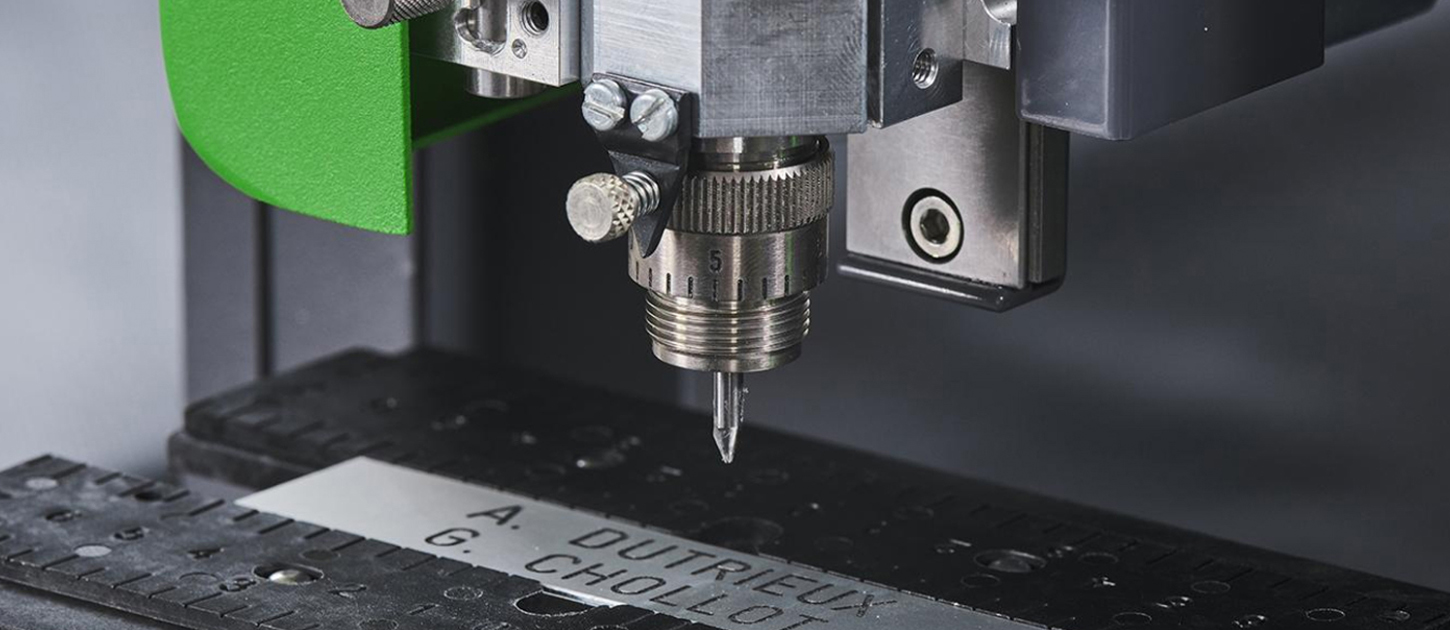

Applications: CNC router 1325 machines are commonly used in woodworking, signage production, furniture making, and various industrial applications. They can produce intricate designs, carve 2D and 3D shapes, and create detailed engravings with precision.

Software: CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software is used to create the design files for CNC routers. Popular software options include AutoCAD, Solid Works, Vectric Aspire, and others.

Dust Collection: Many CNC routers are equipped with dust collection systems to keep the workspace clean and maintain machine performance.

Safety Measures: Safety features like emergency stop buttons, safety interlocks, and protective enclosures are often included to ensure safe operation.