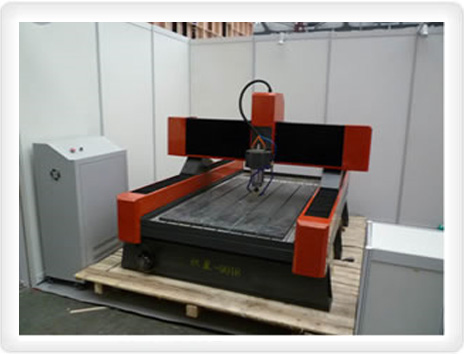

In CNC router machine, the heavy-duty gantry is saddle on the working bed, keeps the spindle movement ready for the operation and helps to minimize the vibrations during cutting. It is used to cut the material accurately, increasing flexibility and stability so decreasing deformation.

The drive system converts to linear motion from the rotational motion and connects to the motor to give higher performance. The X-axis moves the gantry from right to left, Y-axis from left to right and the z-axis moves the spindle movement upwards & downwards.

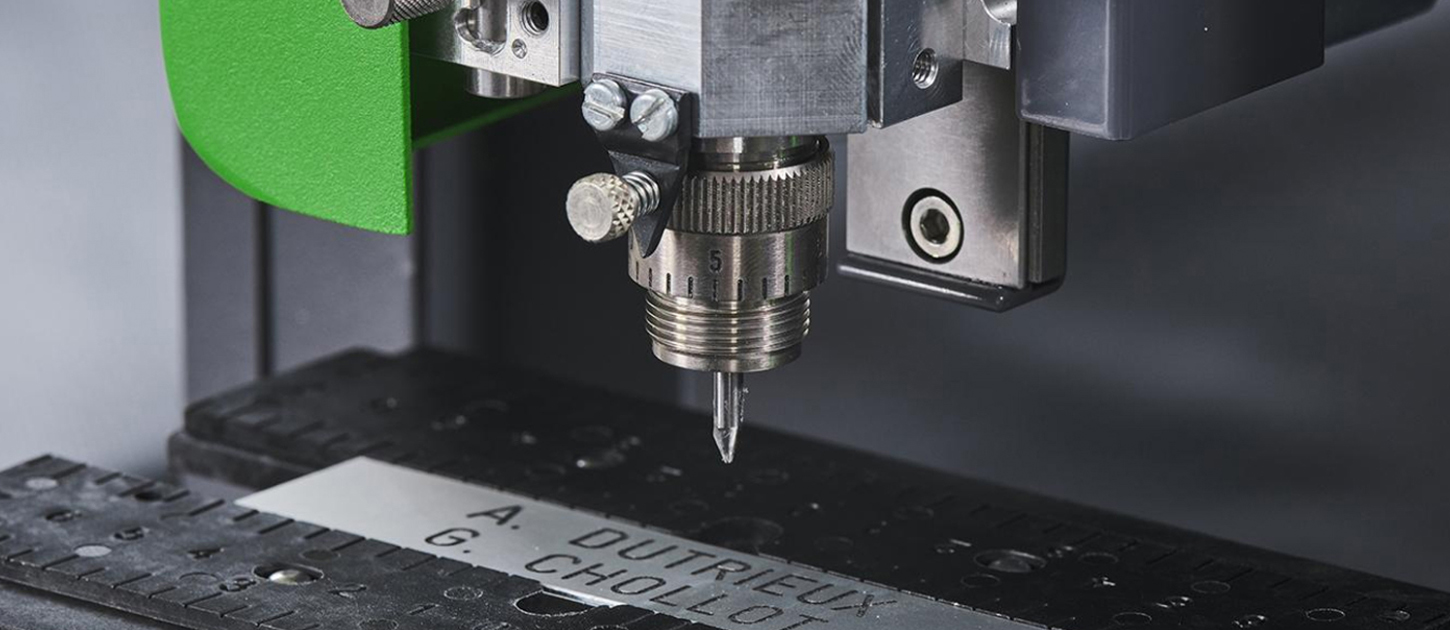

An advanced type of tooling method by computerized programming gives more precision over manual control throughout the process.

The helical rack & pinion drive adjust the rotary motion to linear motion and help to keep the machining position on the perfect rack.

The movement of the CNC router machine tool and rotation of the axis is powered by a stepper motor. It runs faster, more accurate and produces high acceleration while processing.

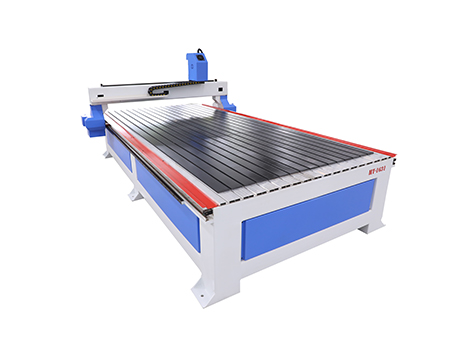

High Range of CNC Router Machine Supplier in Kanyakumari

Selecting the right CNC router machine supplier is a critical decision. Here are some factors to consider when making your choice:

Machine Type: Determine the type of CNC router machine that suits your specific needs. Consider the size, power, and capabilities required for your applications.

Machine Quality: Quality is paramount. Look for suppliers that offer reliable, durable, and well-constructed machines. Check for reviews and testimonials from other customers.

Price Range: Establish a budget that aligns with your financial capabilities. Be cautious of suppliers offering machines at significantly lower prices, as it might indicate inferior quality.

Service and Support: Ensure that the supplier provides excellent customer support, including installation, training, and ongoing maintenance services.

Software Compatibility: Verify that the CNC router machine is compatible with the CAD/CAM software you plan to use.