Some Key Features And Aspects Of 3D Carving Machines:

Computer Control: 3D carving machines are controlled by a computer program that defines the tool’s movements. This program, often generated through software like CAD (Computer-Aided Design) or CAM (Computer-Aided Manufacturing), specifies the precise coordinates and tool paths required to create the desired object.

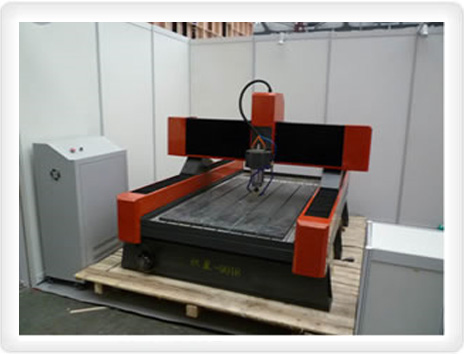

Material Compatibility: These machines can work with a wide range of materials, including wood, plastic, metal, foam, composites, and more. The specific machine and tooling used can vary based on the material being carved.

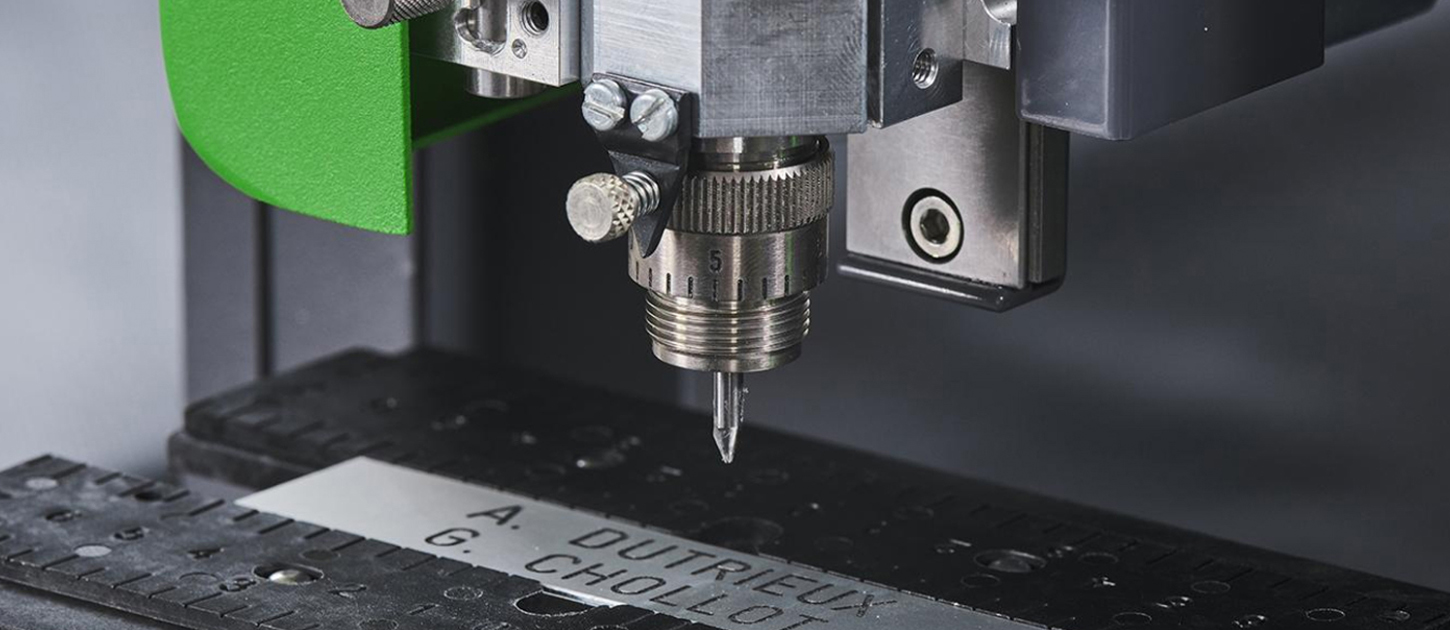

Versatility: 3D carving machines can create intricate designs and complex shapes. They are used in industries like woodworking for carving furniture and decorative items, in metalworking for machining parts, and in sign-making for engraving and cutting.

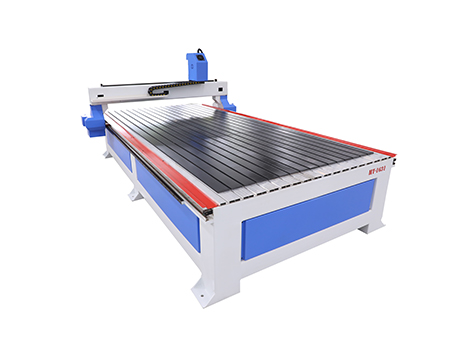

Accuracy and Precision: CNC routers offer high levels of accuracy and repeatability, ensuring that each piece is consistent in quality.

Tooling: The type of cutting or carving tool used depends on the material and the desired outcome. Common tool options include end mills, ball-nose cutters, and V-bits.

Work Area Size: The size of the work area (or bed) varies from machine to machine. Smaller desktop CNC routers are suitable for hobbyists and small-scale projects, while larger industrial machines can handle more extensive workpieces.

Spindle Speed and Power: The spindle (the motor that rotates the cutting tool) can vary in terms of speed and power, which affects the cutting capabilities and the types of materials that can be processed.

Software Integration: The CNC machine is typically controlled through specialized software that translates design files into machine instructions. Popular software options include Mach3, GRBL, and more.

Applications: 3D carving machines have a wide range of applications, including furniture production, cabinetry, mold making, prototyping, jewelry making, and even art and sculpture.

Safety Considerations: Operating CNC routers requires safety precautions, as the rotating tools can be hazardous. Users should be trained on safe operation and follow appropriate safety guidelines.

Maintenance: Regular maintenance is essential to keep the machine running smoothly and extend its lifespan. This includes cleaning, lubrication, and occasional replacement of parts.

3D carving machines come in various sizes and configurations, so choosing the right one depends on your specific needs and budget. Whether you’re a hobbyist or a professional, a 3D carving machine can significantly enhance your ability to create intricate, customized objects with precision and repeatability.